Are you looking for a cost-effective solution to create rubber parts using 3D printing technology? Look no further than ProtoShapes, Inc. We specialize in creating high-quality polyurethane cast parts from 3D printed patterns.

Unlike traditional 3D printing processes that rely on specialized rubber-like materials with poor physical properties, our solution allows for complete customization of the physical properties of the final product. We can cast a variety of rubber formulations to achieve the desired properties, including hardness, rebound, flexural strength, chemical resistance, dielectric and abrasion resistance, and more.

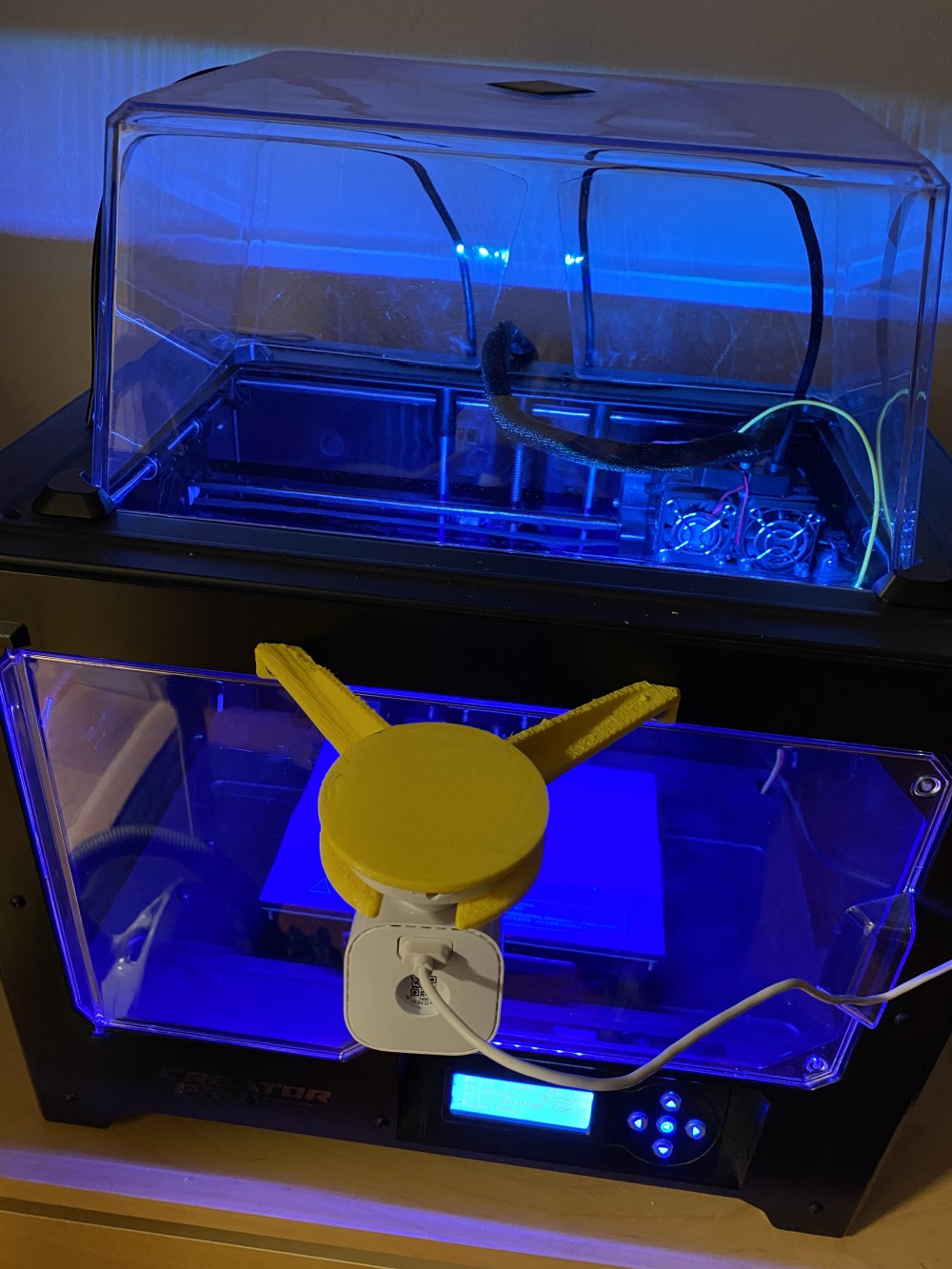

The process is quick, with tooling rendered in just a few days and parts formed in a matter of minutes. Our precision meter mixing equipment ensures consistency and quality in every part produced. Plus, with the ability to produce just a few parts or thousands on demand, we can cater to any quantity requirements.

We take pride in delivering high-quality parts that meet OEM specifications. Upon receipt of your 3D printed pattern, our team will clean up and add a fine texture to ensure a professional-looking finished product.

The best part? Our polyurethane cast parts cost much less than other processes, making it the perfect solution for low volume production or creating just a few prototypes. While there may be a trade-off with tooling costs for high volume production, our solution offers a cost-effective solution for companies looking to create rubber parts through 3D printing.

Don't settle for subpar physical properties with other 3D printing materials. Contact ProtoShapes, Inc. to learn more about our polyurethane cast parts process and see how we can help bring your 3D printed rubber parts to life.